Research & Development

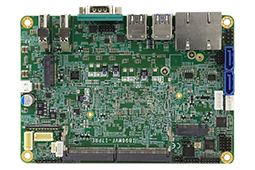

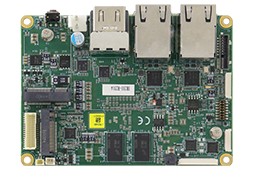

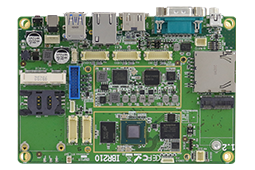

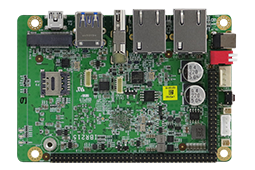

IBASE is committed to innovation, investing heavily in R&D to deliver market-driven and future-ready solutions. Our team of hardware and software experts, many with over 20 years of experience, has built strong core technologies that enable us to respond quickly to market trends. From board-level design to system integration, we create cutting-edge products and customized ODM/JDM solutions. Over the past 25 years, IBASE has developed hundreds of boards and systems, supporting global customers, distributors, and system integrators with reliable, high-performance industrial computing solutions.

R&D Development Capabilities

Hardware Development Capabilities

Advanced Hardware Simulation Tools

Software/Firmware Development Capabilities

Quality & Reliability

To ensure product quality and reliability, IBASE's manufacturing facility uses state-of-the-art machines and effective inspection tools. Error-free pick and place machines precisely place the right components in the exact location. Solder paste thickness measurement, 3D X-ray scan, 3D scope for solder ball inspection and 100% AOI inspection are performed to control the quality of SMT manufacturing in board production. All systems also undergo Hi-Pot testing to assure electrical safety compliance. A Class 10,000 clean room maintains strict standards, with QC staff who implement 100% inspections to prevent contamination problems particularly in the assembly of panel PCs. Furthermore, stringent dust control precautions are taken in the final assembly with the use of dust-proof curtains and special auto-grade spray solutions.

Professional Production Lines

SMT Lines

DIP Assembly Lines

Press Fit

Pre-test

Advanced Manufacturing Facilities

SMT Nitrogen Reflow Ovens

X-Ray Component Counter

3D Automated Optical Inspection

DIP AOI

Reliability & Compatibility Validation

Hardware

Electrical Validation - Low Speed Signal

- Clock / SMBus / SPI Waveform Test

- Intel/AMD Power On Sequence Waveform Test

Electrical Validation - High Speed Signal

- USB / SATA / PCIE / Ethernet Eye Diagram Test

- SFP+ / SFP28 / HDMI / DP Eye Diagram Test

Power Verification

- Transient and Ripple Measurement

- OC/OV Output Protection

- Power On/Off Overshoot

- Power Efficiency Validation

- Multi Phase Synchronous Control Test

- Thermal Compensation Test

Software

Mainstream OS

- Windows or Windows Server

- Linux

Reliability

- 3DMark 11 Advanced Edition

- FurMark

- PassMark BurnInTest for Windows/Linux

- MemTest86 Pro

- MobileMark

- PCMark Advanced Edition

Performance

- Xena Network Throughput Test

- PassMark PerformanceTest

- 3DMark Fire Strike

- 3DMark 11 Advanced Edition

- PCMark 10 Advanced Edition

Our Advantages

Reliability

In house electrical, mechanical and thermal design with hardware/software reliability & compatibility validation.

Longevity

To ensure long-term supply, high-quality components are sourced with effective product lifecycle management.

Performance

Leverages the latest solutions from Tier 1 processor vendors to ensure high levels of computing performance.

Serviceability

Provides comprehensive after-sales services and technical support to ensure complete customer satisfaction.

February 2000

Founded

Taipei, Taiwan

Headquarters

TPEx 8050

Stock Code

.png)

.png)

.png)

.png)